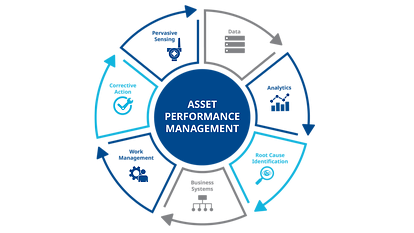

The software that empowers an industrial plant to predict the future health of its machinery is a sophisticated and deeply integrated system. A modern Asset Performance Management Market Platform is far more than a simple dashboard; it is an end-to-end data and analytics architecture designed to transform raw sensor readings into actionable maintenance strategies. The architecture of such a platform is built upon a layered foundation, beginning with the Data Connectivity and Historian Layer. This is the foundational layer responsible for collecting time-series data from a vast and heterogeneous array of sources across the plant floor. It must have a rich library of connectors to communicate with existing operational technology (OT) systems, including Distributed Control Systems (DCS), SCADA systems, and plant data historians (like OSIsoft PI System or Aspen InfoPlus.21). It also needs to be able to ingest data directly from new Industrial Internet of Things (IIoT) sensors via protocols like OPC UA or MQTT. This layer is responsible for securely collecting, compressing, and storing this massive volume of high-frequency data, creating the comprehensive historical record that is essential for training the predictive models.

The second and most critical architectural layer is the Analytics Engine and Digital Twin Framework. This is the intelligent core of the APM platform. It is composed of a suite of advanced analytical tools and machine learning algorithms. This includes first-principle or physics-based models, which use engineering knowledge of how a piece of equipment is supposed to behave, and AI/ML models, which learn patterns directly from the historical data. This engine performs several key functions. Anomaly detection models are used to identify any operational behavior that deviates from the established norm. Diagnostic models can help to identify the specific root cause of an anomaly. The most advanced are the prognostic models, which are used to predict the "Remaining Useful Life" (RUL) of a component. A crucial part of this layer is the digital twin. The platform creates a virtual replica of each physical asset, which provides the essential context for the analytics. The incoming data is mapped to this digital twin, allowing the platform to understand that a specific vibration signal is coming from the outboard bearing of "Pump-101," which is a critical part of a specific production process.

The insights generated by the analytics engine are then operationalized through the Asset Strategy and Workflow Management Layer. An insight is useless if it doesn't lead to an action. This layer provides the tools for reliability engineers to define and manage the optimal maintenance strategy for each asset. Based on an asset's criticality and the predictions from the analytics engine, the engineer can decide on the right approach, whether it's reactive, preventive, or predictive. When the analytics engine generates a predictive alert—for example, "Bearing on Pump-101 has a 90% probability of failure within the next 30 days"—this workflow layer takes over. It can be configured to automatically generate a work order in the company's Enterprise Asset Management (EAM) or Computerized Maintenance Management System (CMMS). This work order will include all the relevant information: the nature of the predicted failure, the supporting data, and a recommended repair procedure. This seamless integration between the APM platform (the "predict" system) and the EAM/CMMS (the "act" system) is what closes the loop and enables a truly proactive maintenance process.

Finally, the entire platform is made accessible to different users through a powerful Visualization and Collaboration Layer. This is the user interface of the APM system, typically a web-based portal with role-based dashboards. A plant manager might see a high-level overview of the overall asset health and risk profile of the entire facility. A reliability engineer will have a more detailed view, allowing them to drill down into the specific sensor data and analytics for a particular piece of equipment. A maintenance technician might access a simplified mobile view that shows them their assigned work orders and provides access to digital work instructions or schematics. This layer is designed to foster collaboration between the operations, maintenance, and engineering teams, providing them with a shared, data-driven view of asset performance. It provides the tools for root cause analysis, case management, and knowledge capture, ensuring that the insights gained from one event can be used to improve the performance of the entire fleet of assets.

Top Trending Reports: