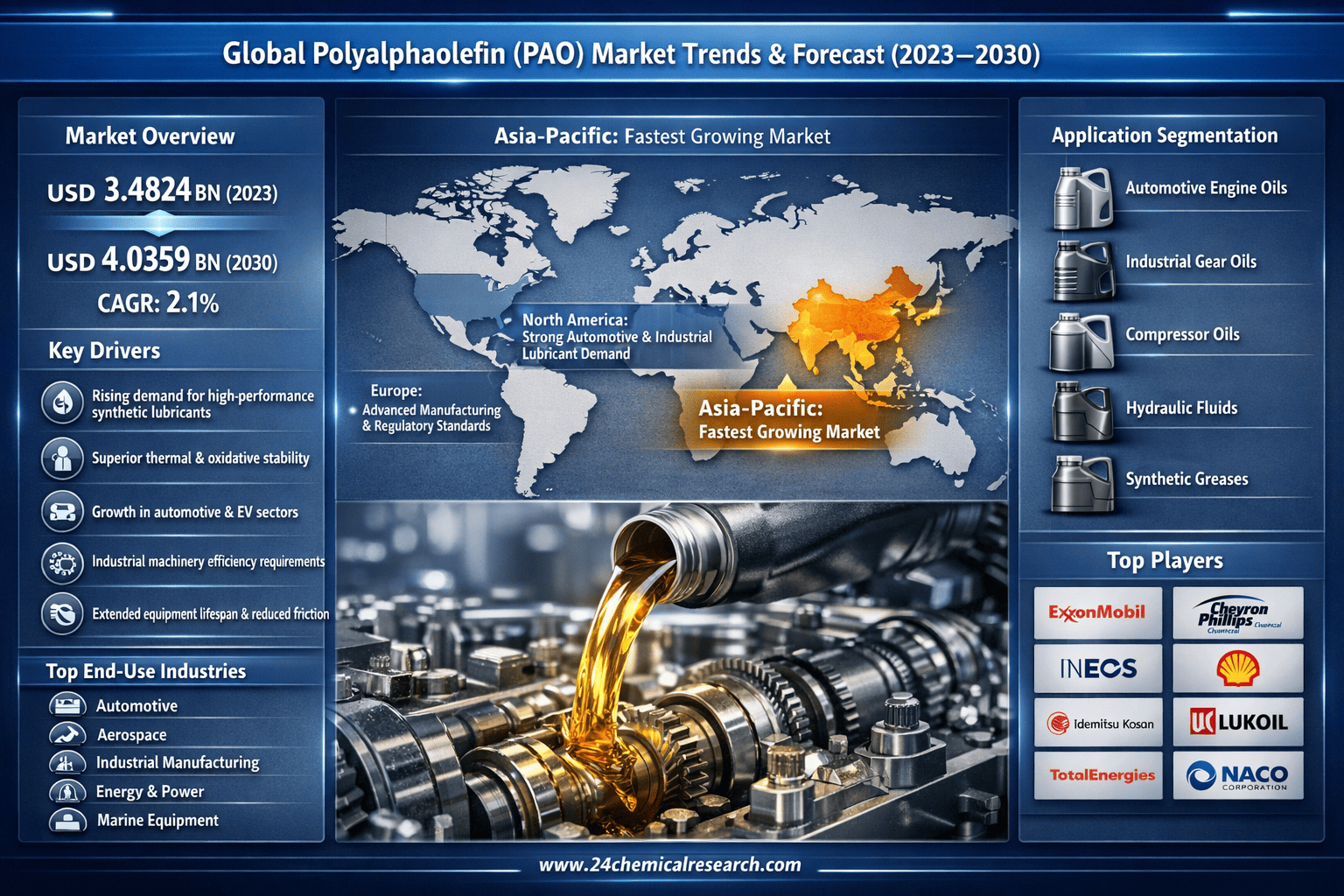

According to 24Chemical Research, Global Polyalphaolefin (PAO) market was valued at USD 3.4824 billion in 2023 and is projected to reach USD 4.0359 billion by 2030, exhibiting a steady CAGR of 2.1% during the forecast period.

Polyalphaolefins, synthetic hydrocarbons derived from ethylene polymerization, have evolved from specialized industrial applications to become essential high-performance lubricants across numerous sectors. Their exceptional properties—including superior thermal stability, excellent viscosity indices, and remarkable oxidative resistance—make them indispensable in demanding environments where mineral oils fall short. Unlike conventional lubricants, PAOs maintain performance across extreme temperature ranges while reducing friction and extending equipment lifespan, making them crucial components in modern machinery and automotive systems.

Get Full Report Here: https://www.24chemicalresearch.com/reports/261591/global-polyalphaolefin-forecast-market-2024-2030-130

Market Dynamics:

The market's evolution is governed by a complex interplay of growth drivers that push boundaries, persistent challenges that require innovative solutions, and emerging opportunities that redefine industry standards.

Powerful Market Drivers Propelling Expansion

-

Automotive Industry Evolution: The automotive sector's relentless pursuit of efficiency represents the primary growth engine for PAOs. With the global automotive industry exceeding $3 trillion annually, manufacturers continuously seek advanced lubricants that enable higher engine performance and longer maintenance intervals. PAO-based synthetic engine oils demonstrate 15-20% better fuel economy compared to conventional oils, while transmission fluids enhanced with PAOs enable smoother shifting and extend component life by 30-40%. The rapid expansion of electric vehicles, where thermal management is critical, has created new demand for PAO-based thermal fluids that maintain optimal battery temperatures in extreme conditions.

-

Industrial Machinery Advancements: Modern manufacturing demands lubricants that can withstand extreme operating conditions. PAOs have become the backbone of industrial lubrication, particularly in gear oils and compressor applications where their thermal stability reduces breakdowns by 25-30%. In wind turbine applications, PAO-based lubricants have demonstrated the ability to extend maintenance cycles from 6-12 months to 18-24 months, significantly reducing operational costs in the rapidly growing renewable energy sector. The global industrial machinery market, valued at over $500 billion, continues to drive PAO adoption as companies seek to maximize equipment uptime and minimize maintenance expenses.

-

Performance Advantages Over Alternatives: PAOs consistently outperform competing synthetic and mineral-based lubricants across multiple parameters. Their hydrolytic stability prevents acid formation in the presence of water, a critical advantage in industrial applications where moisture contamination is common. The narrow molecular weight distribution of PAOs provides consistent viscosity characteristics that remain stable across temperature fluctuations of -40°C to 160°C, making them irreplaceable in aerospace, defense, and extreme environment applications where reliability is non-negotiable.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/261591/